How Manufacturers Benefit from Using EAM Software

Viki Dongare |

08 Apr 2024 |

12:35 PM

- Importance of EAM in the Manufacturing Industry

- Overview of EAM Software Solutions

- The Role of EAM in Asset Management

- Benefits of EAM Software for Manufacturers

- Implementing EAM Systems in Manufacturing

- Advanced Features and Capabilities of EAM Software

- Challenges and Considerations in EAM Implementation

- Conclusion

Role of Work Order in Manufacturing

Pratik Lohiya 12 Apr 2024 | 11:49 AMExplore the evolving landscape of work order management in manufacturing, from preventive maintenance strategies to integration with advanced technologies, driving efficiency and innovation...

Understanding Enterprise Asset Management (EAM)

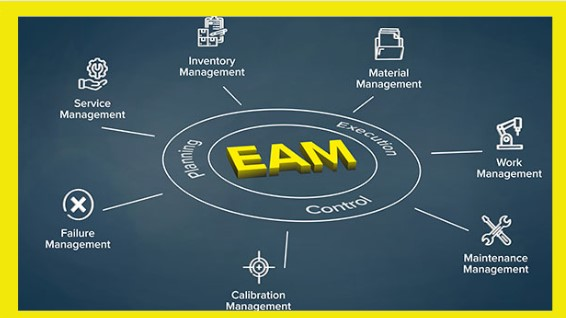

Enterprise Asset Management (EAM) is a comprehensive approach to managing and optimizing the assets and resources of a manufacturing operation. It encompasses various aspects such as asset performance, preventive maintenance, inventory management, and asset tracking. In the manufacturing industry, where physical assets play a crucial role in production processes, effective asset management is paramount for ensuring smooth operations and maximizing productivity.

Importance of EAM in the Manufacturing Industry

EAM software serves as a powerful tool for manufacturers to streamline their asset management processes. By centralizing asset data and maintenance operations, EAM software enables organizations to monitor asset performance, schedule preventive maintenance tasks, and track inventory levels efficiently. This not only helps in reducing downtime and maintenance costs but also enhances overall asset utilization and performance.

Overview of EAM Software Solutions

With the increasing complexity of manufacturing operations and the need for operational efficiency, EAM software solutions have become indispensable for manufacturers looking to stay competitive in today's market. In the following sections, we will delve deeper into the importance of EAM in the manufacturing industry and explore the features and benefits of EAM software solutions.

The Role of EAM in Asset Management

Enterprise Asset Management (EAM) plays a pivotal role in optimizing asset performance and utilization within manufacturing operations. By leveraging EAM software, organizations can effectively monitor the health and performance of their assets in real-time, allowing for timely interventions to prevent downtime and enhance productivity.

Maximizing Asset Performance and Utilization

One key aspect of EAM is maximizing asset performance, which involves monitoring asset health indicators such as uptime, reliability, and efficiency. By analyzing performance data, manufacturers can identify areas for improvement and implement strategies to optimize asset performance, ultimately driving greater operational efficiency.

Optimizing Asset Maintenance and Preventive Tasks

Additionally, EAM facilitates the optimization of asset maintenance and preventive tasks. Through predictive analytics and maintenance scheduling capabilities, organizations can proactively identify maintenance needs and schedule preventive tasks to avoid costly breakdowns and unplanned downtime.

Tracking and Managing Physical Assets Efficiently

EAM systems enable tracking and managing physical assets efficiently by providing a centralized platform for asset inventory management and tracking. This ensures accurate record-keeping and helps in identifying asset location, status, and usage history, streamlining asset management processes and enhancing overall operational effectiveness.

Benefits of EAM Software for Manufacturers

Reducing Maintenance Costs and Downtime

EAM software offers numerous benefits to manufacturers, ranging from cost savings to improved operational efficiency and regulatory compliance. One significant advantage is the reduction of maintenance costs and downtime. By implementing preventive maintenance schedules and optimizing asset performance, organizations can minimize unexpected breakdowns and costly repairs, resulting in substantial savings.

Enhancing Operational Efficiency and Effectiveness

EAM software enhances operational efficiency and effectiveness by streamlining maintenance processes and facilitating data-driven decision-making. Maintenance team can access real-time asset data, prioritize tasks, and allocate resources efficiently, leading to increased productivity and reduced downtime.

Improving Regulatory Compliance and Safety Measures

Enterprise Asset Management software solutions help in ensuring regulatory compliance and safety measures within manufacturing facilities. By maintaining comprehensive records of maintenance activities and asset performance, organizations can demonstrate compliance with industry regulations and implement proactive measures to mitigate safety risks.

Overall, EAM software empowers manufacturers to optimize asset utilization, reduce maintenance costs, and enhance operational effectiveness, ultimately driving sustainable growth and competitiveness in today's dynamic market landscape.

Implementing EAM Systems in Manufacturing

Implementing Enterprise Asset Management (EAM) systems is crucial for optimizing operational efficiency and ensuring the longevity of physical assets. Here's how manufacturers can effectively integrate EAM into their processes:

Integrating EAM with Maintenance Teams and Processes

EAM system acts as a central hub for maintenance teams, providing a unified platform to streamline communication, task assignment, and resource allocation. By integrating EAM with existing maintenance processes, manufacturers can ensure seamless collaboration and coordination among team members, leading to improved response times and faster issue resolution.

Leveraging Data-Driven Decision Making for Asset Management

EAM software empowers manufacturers with actionable insights derived from real-time data analytics. By leveraging predictive maintenance algorithms and performance metrics, organizations can proactively identify maintenance needs, optimize asset performance, and minimize downtime. Additionally, data-driven decision-making enables manufacturers to prioritize tasks effectively, allocate resources efficiently, and forecast future maintenance requirements with greater accuracy.

Understanding the Business Value and ROI of EAM Solutions

Beyond operational improvements, EAM solutions deliver tangible business value and return on investment (ROI) for manufacturers. By reducing maintenance costs, minimizing downtime, and extending asset lifecycles, EAM system contributes to bottom-line savings and increased profitability. Moreover, EAM enables manufacturers to comply with industry regulations, enhance safety measures, and maintain a competitive edge in the market.

Implementing EAM system in manufacturing is essential for driving operational excellence, maximizing asset performance, and achieving sustainable growth. By integrating EAM with maintenance teams and processes, leveraging data-driven decision-making, and understanding the business value of EAM solutions, manufacturers can unlock new opportunities for efficiency, productivity, and success in today's dynamic manufacturing landscape.

Advanced Features and Capabilities of EAM Software

Enterprise Asset Management (EAM) software offers a wide array of advanced features and capabilities designed to meet the unique needs of asset-intensive industries and businesses. Here are some key aspects that highlight the sophistication and effectiveness of modern EAM solutions:

Cloud-Based EAM Solutions for Accessibility and Scalability

Cloud-based EAM software provides unparalleled accessibility and scalability, allowing users to access critical asset information from anywhere, at any time. This flexibility is particularly beneficial for asset-intensive industries with distributed operations or remote teams, enabling seamless collaboration and real-time decision-making.

Predictive Maintenance and Asset Performance Analytics

One of the standout features of EAM software is its predictive maintenance capabilities. By leveraging advanced analytics and machine learning algorithms, EAM systems can forecast equipment failures and performance degradation before they occur. This proactive approach to maintenance helps organizations minimize downtime, optimize asset utilization, and extend asset lifecycles.

Centralized Databases for Complete Asset Information Management

EAM software offers centralized databases that serve as repositories for comprehensive asset information. From equipment specifications and maintenance histories to warranty details and inspection reports, these databases provide a single source of truth for all asset-related data. This centralized approach facilitates efficient asset management, enabling users to track assets, manage maintenance schedules, and monitor performance metrics with ease.

Integration with IoT Devices and Sensor Networks

Modern EAM solutions often integrate with Internet of Things (IoT) devices and sensor networks to collect real-time data on asset health and performance. By monitoring key parameters such as temperature, vibration, and energy consumption, EAM system can identify potential issues early and trigger maintenance actions automatically. This integration enhances operational efficiency, reduces maintenance costs, and improves overall asset performance.

Enhanced Reporting and Analytics Tools

EAM software comes equipped with robust reporting and analytics tools that empower users to gain actionable insights into asset performance and maintenance operations. From customizable dashboards and KPI tracking to advanced reporting capabilities and trend analysis, these tools enable organizations to make data-driven decisions and continuously improve their asset management strategies.

The advanced features and capabilities of EAM software play a critical role in helping asset-intensive industries and businesses maximize asset utilization, improve maintenance management, and achieve operational excellence. By leveraging cloud-based solutions, predictive maintenance algorithms, centralized databases, IoT integration, and advanced analytics tools, organizations can unlock new levels of efficiency, reliability, and profitability in their asset management practices.

Challenges and Considerations in EAM Implementation

Implementing Enterprise Asset Management (EAM) solutions can be a transformative process for asset-intensive industries, but it also comes with its own set of challenges and considerations. Here are some key factors to keep in mind when embarking on an EAM implementation journey:

Addressing Common Pitfalls and Operational Challenges

EAM implementation may encounter obstacles such as data silos, inconsistent asset data, and outdated maintenance processes. It's crucial to address these challenges by conducting a thorough assessment of existing workflows, identifying pain points, and designing tailored solutions to streamline operations.

Overcoming Resistance to Change and Ensuring User Adoption

Resistance to change is a common barrier to successful EAM implementation. To overcome this challenge, organizations must prioritize change management initiatives and engage stakeholders at all levels of the organization. Providing comprehensive training and clear communication about the benefits of EAM can help foster buy-in and ensure widespread user adoption.

Integrating EAM with Existing Systems and Processes

Seamless integration with existing systems and processes is essential for maximizing the value of EAM solutions. Whether it's integrating with ERP systems, SCADA systems, or IoT devices, organizations must ensure interoperability and data exchange between different platforms to avoid data fragmentation and duplication.

Addressing Regulatory Compliance and Safety Concerns

Asset-intensive industries, such as healthcare and construction, must comply with stringent regulatory requirements and safety standards. EAM implementation should prioritize adherence to industry regulations and safety protocols to mitigate risks and avoid costly fines.

Optimizing Maintenance Strategies and Asset Lifecycle Management

EAM implementation provides an opportunity to reevaluate maintenance strategies and optimize asset lifecycle management. Organizations must strike a balance between reactive maintenance and preventive maintenance, leveraging EAM tools to schedule routine tasks, execute preventive maintenance, and proactively manage physical assets to maximize uptime and performance.

While EAM implementation presents numerous benefits for asset-intensive industries, it's essential to anticipate and address the challenges and considerations that may arise along the way. By addressing common pitfalls, overcoming resistance to change, integrating with existing systems, ensuring regulatory compliance, and optimizing maintenance strategies, organizations can successfully implement EAM solutions and unlock their full potential in improving overall asset performance and operational efficiency.

Conclusion

Enterprise Asset Management (EAM) software emerges as a cornerstone for asset-intensive industries, offering unparalleled capabilities to optimize asset performance, streamline maintenance operations, and drive sustainable growth. Through this comprehensive approach, manufacturers can maximize asset utilization, reduce maintenance costs, and enhance overall operational efficiency.

The benefits of EAM implementation are manifold. By leveraging cloud-based EAM solutions, organizations gain accessibility and scalability, empowering users to access critical asset information from anywhere, at any time. Predictive maintenance and asset performance analytics enable proactive maintenance strategies, minimizing downtime and extending asset lifecycles.

Centralized databases provide a single source of truth for asset information, facilitating efficient asset management and ensuring regulatory compliance. Integration with IoT devices and sensor networks allows for real-time monitoring of asset health, enabling organizations to identify issues early and trigger maintenance actions automatically.

EAM software also offers enhanced reporting and analytics tools, empowering users to make data-driven decisions and continuously improve asset management strategies. This sophisticated approach not only improves asset performance but also enhances overall operational efficiency, reduces risks, and ensures compliance with industry regulations.

However, implementing EAM solutions comes with its own set of challenges, including resistance to change, data integration issues, and regulatory compliance concerns. To overcome these challenges, organizations must prioritize change management initiatives, engage stakeholders, and ensure seamless integration with existing systems and processes.

While the road to EAM implementation may present hurdles, the benefits far outweigh the challenges. By addressing common pitfalls, optimizing maintenance strategies, and leveraging advanced EAM capabilities, organizations can unlock new opportunities for efficiency, reliability, and profitability in their asset management practices. Ultimately, EAM software stands as a powerful tool for driving innovation, enhancing competitiveness, and achieving operational excellence in today's dynamic manufacturing landscape.